|

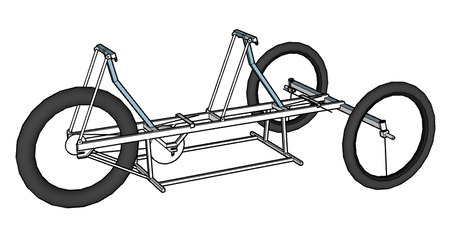

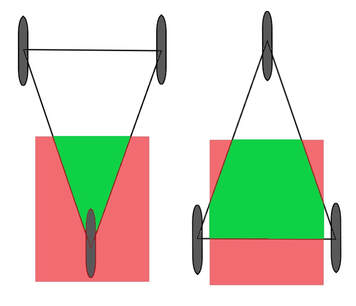

3/23/2023 2 Comments A Major Re-visionIn my last post, I cited the problems associated with the Raven - the long, wide, tandem-seating electrified trike. Among the problems were weight, convoluted & unreliable chain routing, overly complicated steering, kingpin flex issues from side loads and traction problems on inclines with no passenger. The design I had in mind to address these issues is indeed simpler. It uses a straight crossmember up front, more upright seating and simple chain routing, and it would certainly be much lighter. However, one issue that it did not address was usability. With a width of nearly 4 feet (1.22 meters), the sheer size of that proposed redesign and the resulting fairing/overall vehicle would have relegated it and the trike before it to the streets only. I would not have felt responsible bringing such a vehicle onto bike paths, and I did not want to create something that I could only use on roads shared with cars. I came across a short article by "The Left-Handed Cyclist" on their blog that highlighted a couple of the challenges facing vehicles such as the one I'm designing. That article can be read here. In it, they go through a few examples of vehicles past that were based on electrified tricycles, with fairings, that were designed to bridge the gap between bicycles and cars. One such issue is trying to use a low-speed (at or below 30 mph (48 kph) crusing speed on a roadway shared with cars. This speed (with a large enough vehicle, such as an ELF or PEBL velomobile, or the one I was designing) can lead to traffic backups as motorists are forced to pass in a passing lane. While this may not seem like an issue on paper, I know from experience that driving a vehicle slowly enough for motorists around you to need to pass constantly is a stressful experience for the one operating the slow-moving vehicle. People are often angry and passing aggressively, and therefore dangerously, when they feel their movement is being impeded. This is a very unpleasant experience, and not one I want to have whenever I am running errands around town, so I've decided that it is critically important for this vehicle to easily fit on bike paths (and bike lanes) responsibly. So, what does this mean for the trike? It means that things need to get smaller. Much smaller. So, my focus lately has been on packaging. How can I create something that's easy and appropriate to use by myself, but can still carry plenty of cargo or a passenger if the need arises? I basically want to create a bakfiets (box bike) - but it needs to be able to have a fairing mount to it so that the operator (not just the cargo/passenger(s) like the Urban Arrow and other cargo bikes) can be protected from the elements. The more I've thought about this problem, the more I begin to look to delta tricycles. Delta tricycles offer a few unique advantages. One of those is having a large open space for cargo between the rear wheels. This is a fantastic place to put a lot of weight, because the more weight you have there, the better your stability gets. To illustrate this point, see the figure below. All things being the same - wheelbase, track width and cargo area - you can see that the area within the tire contact patch triangle is far greater with the delta design. With a tadpole trike, cargo areas are beside, in front of and above the rear wheel. This is a very awkward way to carry cargo, as most weight placed around the rear wheel (other than that placed in front of it) serves to fight the inherent stability of tadpole layouts.

Complex Design

Arguably, one of the most frustrating things to deal with for any end-user of a product is over-complicated, unintuitive design. Standard bicycles are one of the simplest machines humanity has created, yet I would argue that the utility of bicycles cannot be overstated. Anybody with a little mechanical aptitude (and perhaps some YouTube search prowess) can fix just about anything on a normal bicycle. As soon as one starts to introduce steering linkages, suspension, differentials and jackshafts into a bicycle design, the vehicle starts to become more of, well... a vehicle. I want to make sure that this trike is not only easy to build, but easy and inexpensive to maintain, work on and live with. To that end, I believe I've found the simplest, most streamlined way to create a cargo trike in a small package that's simple in design and does not require any crazy transmission or steering linkages, is intended for use on bicycle paths, can fit through a normal doorway, sits low to the ground for stability and has a wheelbase that's nearly 2-feet shorter than your typical box bike, while being able to carry the same cargo. As you can probably guess, it's a delta design, but the drivetrain is simpler than you may expect. I'm very excited to share progress pictures once this build is underway!

2 Comments

John Verkler

5/11/2023 01:17:04 pm

Sir, this tadpole trike seems to resemble a plan from Atomic Zombie, out of Canada?

Reply

Chase

5/17/2023 08:04:31 am

Hi John! Thanks for reaching out -

Reply

Leave a Reply. |

Archives

March 2024

Categories |

Search by typing & pressing enter